Izikhongozeli zePlastiki zikho kuzo zonke iindawo zobomi, ukusuka ekupakishweni kokutya ukuya kwizisombululo zokugcina, imfuno yezikhongozeli zeplastiki iyaqhubeka nokunyuka, kwaye ngokufanelekileyo inokuba negalelo kuphuhliso loomatshini abayilelwe ukuvelisa ngokufanelekileyo izitya. Kwicandelo elilandelayo, siza kujonga kwiindidi ezahlukeneyo zoomatshini bezikhongozelo zeplastiki kunye neenkqubo ezibandakanyekayo ekwenzeni izikhongozeli zeplastiki.

Oomatshini bezikhongozelo zePlastiki babhekisa kwizixhobo ezikhethekileyo ezisetyenziselwa ukuvelisaizitya zeplastiki. Lo matshini ugubungela uluhlu lwetekhnoloji kunye neenkqubo, kubandakanya ukubumba inaliti, ukubumba ukuvuthela, kunye ne-thermoforming, kwaye indlela nganye ineengenelo zayo ezizodwa kwiintlobo ezahlukeneyo zezikhongozeli zeplastiki.

1. I-Injection Molding Machines

Enye yezona ndlela zixhaphakileyo zokwenza izikhongozeli zeplastiki, ukubumba inaliti kubandakanya ukunyibilikisa iipeliti zeplastiki kunye nokutofa iplastiki etyhidiweyo kwisingundo. Emva kokuba iplastiki ipholile kwaye iqinile, ukubumba kuyavulwa kwaye isitya esigqityiweyo sitofwe.

Iimpawu eziphambili zomatshini wokubumba inaliti:

-Ukuchaneka: oomatshini bokubumba inaliti baziwa ngokukwazi kwabo ukuvelisa iimilo ezicacileyo, eziyinkimbinkimbi kunye nokunyamezela okuqinileyo.

-Speed: I-injection molding inexesha elifutshane lomjikelo, elivumela ukuveliswa kobuninzi.

-I-Versatility Material: I-injection molding ingasebenzisa uluhlu olubanzi lwe-thermoplastics, iyenze ifaneleke kwizicelo ezahlukeneyo.

Ukubunjwa kwe-injection kukulungele ukuveliswa kwezikhongozeli ezifana neengqayi, iibhotile kunye nezinye izisombululo zokupakisha eziqinileyo.

2. Vuthela oomatshini bokuBumba

Ukubumba ukuvuthela yenye indlela eqhelekileyo yokuvelisaizitya zeplastiki, ngakumbi izitya ezingenanto ezifana neebhotile. Inkqubo iqala ngokudala i-tubular mold yeplastiki engenanto. I-parison ifakwa kwi-mold apho umoya uvuthelwa ukwandisa iplastiki kwaye wenze ukumila kobumba.

Iimpawu eziphambili zoomatshini bokubumba:

-Ukusebenza okuphezulu: ukubumba ukuvuthela kusebenza kakhulu ekuveliseni izixa ezikhulu zezikhongozeli ezingenanto.

-Izikhongozeli zokukhanya: Le ndlela ivumela ukuveliswa kwezixhobo ezilula, ezinciphisa iindleko zokuthutha kunye nefuthe lokusingqongileyo.

-Iintlobo ngeentlobo zeemilo: ukubumba ukuvuthela kunokuvelisa izikhongozeli zeemilo ezahlukeneyo kunye nobukhulu, ukusuka kwiibhotile ezincinci ukuya kwizikhongozeli ezinkulu zemizi-mveliso.

Ukubumba ukuvuthela ngokuqhelekileyo kusetyenziselwa ukwenza iibhotile zesiselo, izitya zokucoca kunye nezinye iimveliso ezifanayo.

3. Umtshini weThermoforming

I-Thermoforming yinkqubo yokufudumeza i-sheet yeplastiki de ibe yinto enokuphepheka kwaye emva koko uyibumbe kwimo ethile usebenzisa i-mold. Iplastiki ipholisa phantsi kwaye igcine imilo yesikhunta, okukhokelela kwisitya esigqityiweyo.

Iimpawu eziphambili zoomatshini be-thermoforming:

-Indleko esebenzayo: i-thermoforming idla ngokuba yindleko ngaphezu kokubumba inaliti okanye ukubunjwa kokuvuthela xa uvelisa izikhongozeli kunye neetreyi.

-I-prototyping ekhawulezayo: Le ndlela ivumela ukuguqulwa koyilo olukhawulezayo, okwenza ukuba ifanelekele i-prototyping kunye nemveliso encinci ye-batch.

-Ukusebenza kakuhle kwezinto: I-Thermoforming ivumela ukusetyenziswa ngokufanelekileyo kwezinto ezichithwayo kunye nokunciphisa inkunkuma.

I-Thermoforming iqhele ukusetyenziswa ukuvelisa izitya zokutya, ukupakishwa kwe-clamshell kunye neekomityi ezilahlayo.

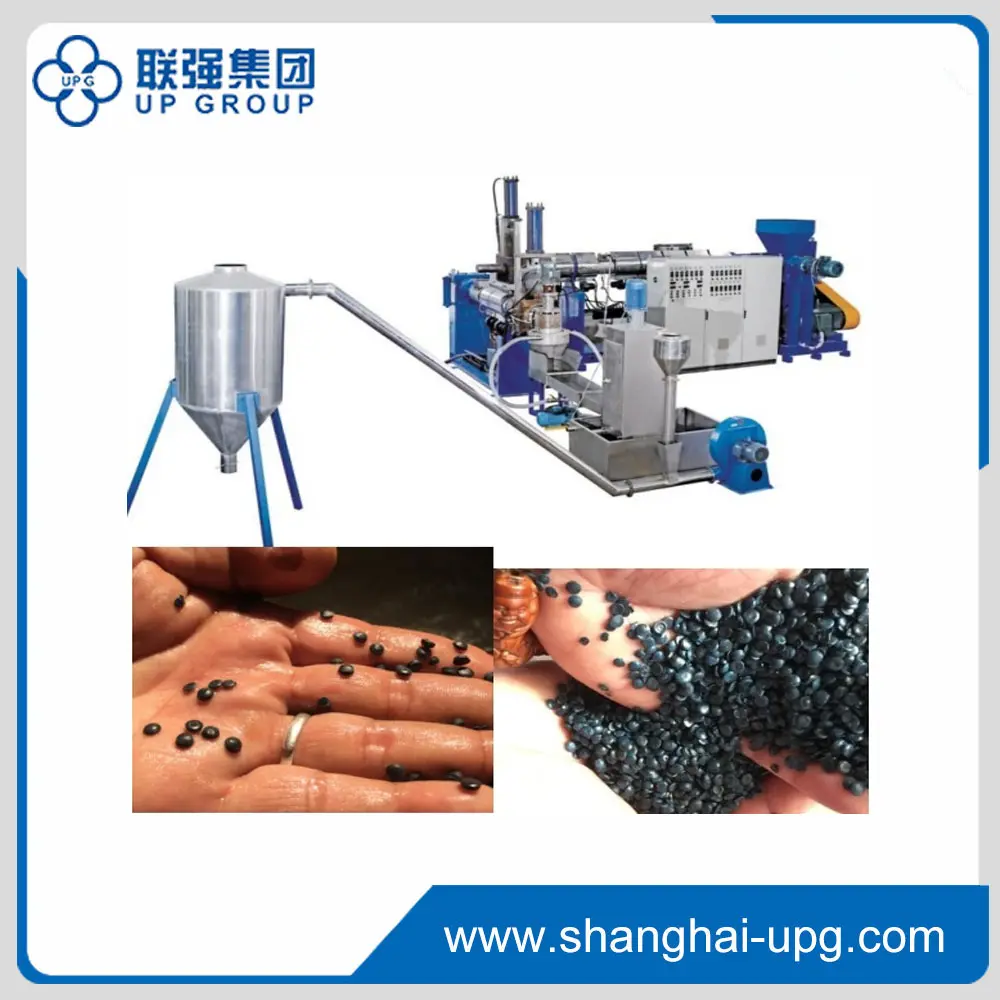

Ungajonga le iveliswe yinkampani yethu,I-LQ250-300PE iFilimu enenqanaba eliphindwe kabini lomgca wokuPelletizing

Indima ye-Automation kwi-Plastic Container Machinery

Ngokuchasene nemvelaphi yenkqubela phambili yetekhnoloji, i-automation iye yaba yinxalenye engafikelelekiyo yokwenza izikhongozelo zeplastiki, kunye neenkqubo ezizenzekelayo zokwandisa imveliso, ukunciphisa iindleko zabasebenzi kunye nokuphucula ukuhambelana kwemveliso. Oomatshini abaninzi beplastiki bale mihla baxhotyiswe ngezi zinto zilandelayo:

-Ukuphathwa kweRobhothi: Iirobhothi zinokulayisha kwaye zikhuphe iimbumba ngokuzenzekelayo, zinyusa isantya kunye nokunciphisa umngcipheko wempazamo yomntu.

- Ukubeka iliso ngexesha langempela: Iinzwa kunye nesoftware zinokubeka iliso kwinkqubo yokuvelisa ngexesha langempela ukwenzela ukuba uhlengahlengiso lwenziwe ngokukhawuleza ukugcina umgangatho.

- Ukudibanisa kunye nezinye iinkqubo: Izixhobo ezizenzekelayo zinokudibaniswa nolawulo lwe-inventri kunye neenkqubo zokubonelela ngokusebenza ngokungenamthungo.

Imiba yokusingqongileyo: Njengoko ulwazi lokusingqongileyo lukhula, abavelisi baya begxila ngakumbi ekuzinzeni, ekuhlaziyeni izinto ezisetyenzisiweyo kunye nokuphuhlisa iiplastiki ezinokubola. Ukuphuhliswa ngakumbi koomatshini kunye nezixhobo kuya kwenza inkqubo yokuvelisa isebenze ngakumbi, ngaloo ndlela kuncitshiswe inkcitho kunye nokusetyenziswa kwamandla.

Isishwankathelo, ukuveliswa kweizitya zeplastikiixhomekeke kwiintlobo ngeentlobo zoomatshini abakhethekileyo, ngamnye kubo ulungele inkqubo yokuvelisa eyahlukileyo. Isitofu sokubumba, ukubumba ukuvuthela kunye ne-thermoforming zezona ndlela zisetyenziswayo ukwenza ezi mveliso zisisiseko. Ukuzenzekela kunye nokuzinza kuya kudlala indima ephambili kwinguquko yokwenziwa kwezikhongozelo zeplastiki. Kubantu abafuna ukungena kumzi-mveliso weplastiki okanye abafuna ukwandisa umthamo wemveliso, kubalulekile ukuqonda oomatshini kunye nezixhobo ezibandakanyekayo kule nkqubo. Abantu abanomdla kwindlela yokwenza izitya zeplastiki okanye abanesidingo sokuzithenga, ncedaQhagamshelana nathi, sinobuchwepheshe obuphambili kunye neenjineli ezinamava.

Ixesha lokuposa: Dec-30-2024