I-Pelletising, inkqubo ephambili ekuvelisweni kweemveliso zeplastiki, igxile ekuhlaziyweni nasekuveliseni iipeliti zeplastiki, eziyimathiriyeli ekrwada yezicelo ezahlukeneyo ezifana nokuveliswa kwefilimu, ukubunjwa kwenaliti kunye nokukhutshwa. Kukho inani letekhnoloji ye-pelletising ekhoyo, phakathi kwayo ifilimu ye-bi-stage umgca wokuvelisa i-pelletising ibonakala njengento exhotyiswe ngakumbi ngokufanelekileyo kunye nokusebenza kakuhle ukuvelisa iipelisi eziphezulu ezivela kwizinto ezilahlwayo zeplastiki.

Ukuguqula izinto eziluhlaza ezifana neeplastiki zenkunkuma zibe zincinci, iipellet ezifanayo yinkqubo yokukhupha, kwaye yonke inkqubo ye-pellettising ibandakanya, ukutyisa, ukunyibilika, ukukhupha, ukupholisa kunye nokusika ukudala iipelisi ezinokuthi ziphathwe ngokulula, zithuthwe kwaye zicutshungulwe kwizigaba ezilandelayo zokuvelisa.

Itekhnoloji yePelletizinginokwahlulwa ngokubanzi ibe ziindidi ezimbini: inqanaba elinye kunye nenqanaba elinye le-pelletising. I-pelletising enenqanaba elinye isebenzisa i-extruder enye ukunyibilikisa izinto kwaye yenze iipellets, ngelixa i-pellettising enezigaba ezibini isebenzisa ii-extruders ezimbini, ezivumela ukulawulwa ngokuchanekileyo kwenkqubo yokunyibilika kunye nokupholisa, okukhokelela kwiipellets eziphezulu.

Ifilimu enamanqanaba amabiniumgca wepelletisingyenzelwe ukusetyenzwa kweefilimu zeplastiki ezifana ne-polyethylene (PE) kunye ne-polypropylene (PP). Itekhnoloji ilungele ukurisayikilisha iifilim zeplastiki zasemva kwabathengi, ezihlala kunzima ukuziqhuba ngenxa yokuxinana kwazo kunye notyekelo lokunamathelana.

Ukutya kunye nokulungiswa kwangaphambili kubandakanya ukondla kuqala inkqubo nge-scrap yefilimu yeplastiki, edla ngokukrazulwa ibe ngamaqhekeza amancinci ukuze kube lula ukuphatha kunye nokusebenza. Unyango lwangaphambili lusenokuquka ukomisa imathiriyeli ukususa ukufuma, okuyimfuneko ekunyibilikeni okuphezulu kunye nokunyibilika.

Kwinqanaba lokuqala, ifilimu yeplastiki ekhutshiweyo ifakwe kwi-extruder yokuqala, exhotywe nge-screw enyibilikisa izinto ngokucheba ngomatshini kunye nokufudumeza. Iplastiki enyibilikisiweyo inyanzeliswa kwikhusi ukususa ukungcola kunye nokuqinisekisa ukunyibilika okufanayo.

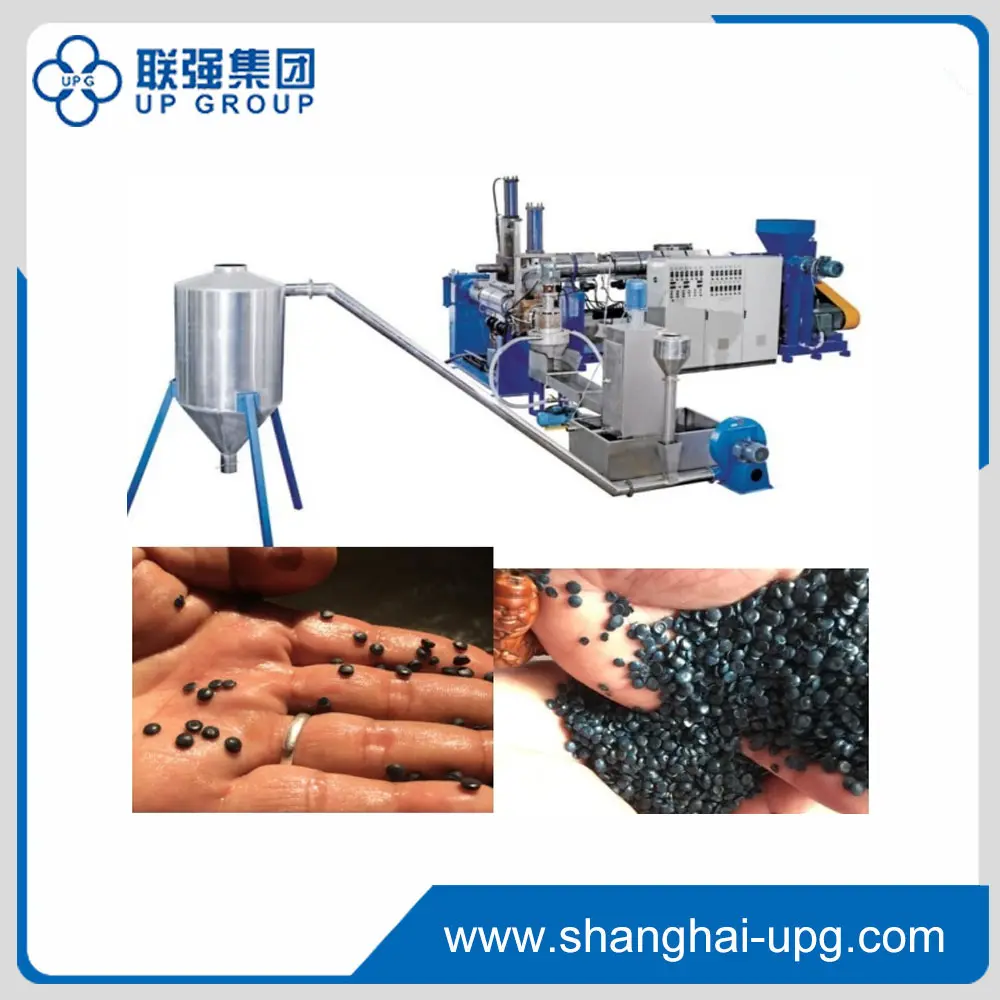

Faka, nceda uqwalasele le mveliso yenkampani yethu,I-LQ250-300PE iFilimu enenqanaba eliphindwe kabini lomgca wokuPelletizing

Ukususela kwi-extruder yokuqala, izinto ezityhidiweyo zidlulela kwi-extruder yesibini, isiteji esivumela i-homogenisation eyongezelelweyo kunye ne-degassing, okuyimfuneko ukususa nayiphi na i-volatiles eseleyo okanye umswakama onokuchaphazela umgangatho we-pellet yokugqibela. I-extruder yesibini idla ngokuqhutyelwa ngesantya esisezantsi, esinceda ukugcina iimpawu zeplastiki.

Emva kwesigaba sesibini se-extrusion, i-pelletiser isetyenziselwa ukusika iplastiki etyhidiweyo kwiipellets, ezinokupholiswa phantsi kwamanzi okanye ngomoya, kuxhomekeke kwiimfuno ezithile zenkqubo yokuvelisa. Iipellets eziveliswayo zifana nobukhulu kunye nokuma kwaye zifanelekile kwiintlobo ezahlukeneyo zezicelo.

Emva kokuba iipellet zibunjiwe, kufuneka zipholile kwaye ziqiniswe, kwaye zomiswe ukuze zisuse umswakama obuninzi. Ukupholisa okufanelekileyo kunye nokomisa kubalulekile ukuqinisekisa ukubaiipilisibagcine ingqibelelo yabo kwaye bangabhibhi.

Ekugqibeleni, iipellet zipakishwe ukuze zigcinwe okanye zithuthwe, inkqubo eyenzelwe ukunciphisa ungcoliseko kunye nokuqinisekisa ukuba iipellets zikwimeko efanelekileyo phambi kokusetyenziswa.

Apha ngezantsi kukho imizekelo yeenzuzo zomgca wenqanaba eliphindwe kabini lokwenziwa kweefilim:

-Umgangatho ophezulu wepellet:inkqubo yamanqanaba amabini ivumela ulawulo olungcono lwenkqubo yokunyibilika kunye nokupholisa, okubangela ukuba iipellets eziphezulu eziphezulu kunye neepropati eziphuculweyo zomzimba.

-Ukususwa okuphezulu kongcoliseko:Inkqubo ye-extrusion yamanqanaba amabini isusa ngokufanelekileyo ukungcola kunye nokuguquguquka, okubangela ukuba i-pellets ecocekileyo, ehambelanayo.

-Ukuguquguquka:Itekhnoloji inokusebenza uluhlu olubanzi lweefilimu zeplastiki, iyenze ifaneleke kwiinkqubo ezahlukeneyo zokuphinda isetyenziswe.

-Ukusebenza kakuhle kwamandla:Iinkqubo ze-bipolar ngokuqhelekileyo ziyilelwe ukuba zidle amandla amancinci kuneenkqubo zenqanaba elinye, zizenze zibe yindlela ezinzileyo.

-Ukuncitshiswa kwexesha lokuphumla:uyilo olusebenzayo lwefilimu ye-bi-stage pelletising line kunciphisa ixesha lokuphumla ngexesha lemveliso, okukhokelela ekwandeni kwemveliso kunye nemveliso.

Itekhnoloji yePelletizing idlala indima ebalulekileyo ekusetyenzisweni kwakhona nasekuveliseni iimveliso zeplastiki. Ifilim imigca ye-pelletising enemigangatho emibini imele intuthuko enkulu kule ntsimi, ukuphucula ukusebenza kakuhle, umgangatho kunye nokuguquguquka. Njengoko imfuno yezisombululo zeplastiki ezizinzileyo ziqhubeka zikhula, ukubaluleka kokusebenzaiteknoloji ye-pelletizingziya kwanda mihla le. Ngokutyalomali kwiinkqubo eziphambili ezifana nefilimu yemigangatho emibini yemigca yepellettising, abavelisi banokuba negalelo kwikamva elizinzileyo ngelixa behlangabezana neemfuno zabathengi babo, ngoko ke ukuba unomdla kwifilimu imigca yepelletising enezigaba ezibini, nceda unganqikazi ukuqhagamshelana nenkampani yethu.

Ixesha lokuposa: Dec-30-2024